- Call Us On

+91 9890135193

- Mail Us On

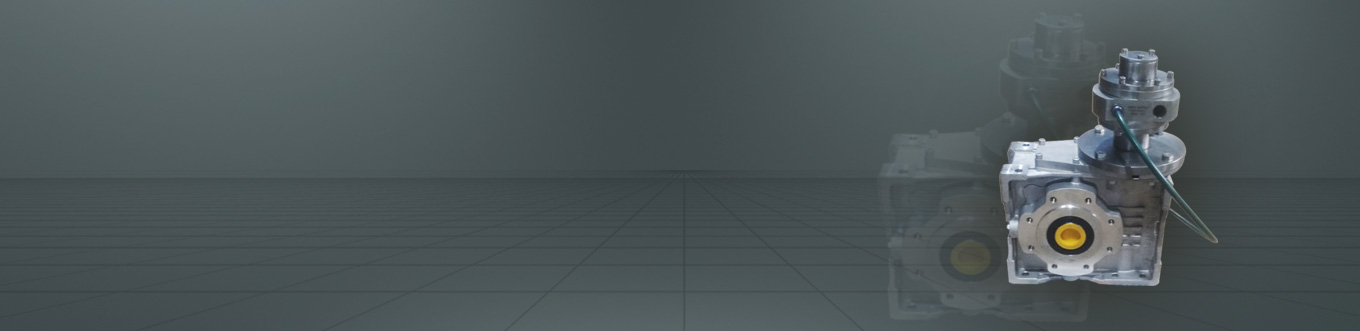

Compact Geared Air Motors :: DAM-7FG-MPGB-4.8

| KW | 0.48 |

| HP | 0.65 |

| Free Speed RPM | 3000 |

| Operating Speed RPM | 2000 |

| Stall Torque Nt-Mt | 5.5 |

| Operating Torque Nt-Mt | 3.3 |

| Rotation | Reversible |

| Air Inlet Port BSP | 1/4" |

| Air Outlet Port BSP | 1/4" |

| Mounting | Flange |

| Air Pressure Max Kg/cm2 | 6 |

| Air Consumption M3/min | 0.75 |

| Air Hose Size mm | 10 x 12 |

| Air House Length mtrs | 3 |

| Weight kg | 1.6 |

Performance Curves

Dimensions & Specifications

Operating Instructions

Installation

- ID of the air line connecting to the air motor should be minimum 10 mm. This will give sufficient air flow to the air motor for running.

- Length of the air hose should be as minimum as possible. It should not exceed 3 meters. If the length is longer than 3 meters, there is a possibility of drop of air pressure an also drop of air flow rate.

- Air pressure at the inlet of the air motor should be minimum 4 kg/cm2. It should not be more than 6 kg/cm2.

- Air should not have water content. It should be lubricated.

- If manual or solenoid valves are used, they should be of ½" port size so as to allow the required flow and pressure of the air.

- Use the Mini Ball Valve supplied by us for speed control. Do not use needle valves.

Operation

- Hold the motor securely and connect it to the air line by using the connection and the Mini Ball Valve.

- There are two ports of ¼"BSP size to the motor. When the air supply is given to one port, exhaust air will come out of the second port. A silencer should be connected to the second port to reduce the noise. The motor will start rotating in one direction.

- For changing the direction of rotation, interchange the ports. Alternatively, a 5/3 direction control valve of ½" size can be used.

- Ensure that lubrication is always given to the motor.

- The speed of the air motor can be varied by varying the inlet air pressure. Install a pressure regulator at the inlet of the air motor for this purpose

Troubleshooting & Repairs

- If the air motor does not start, remove it from the load, disconnect the air supply.

- Separate air motor portion from the gearbox of the motor by removing the four allen screws on the square flange.

- Check the gearbox for free running by holding the gearbox in a vice and by rotating the shaft by a spanner.

- If the gearbox is not rotating, open it by lightely hammering out the pinion holder. Check whether the gears are damaged or the ball bearings are damaged. Replace them and assemble back and check the gearbox for free running.

- If the gearbox is OK, check the air motor by connecting it to the air supply.

- If the air motor does not start, remove the airconnection.

- Check whether the rotor is free by rotating it by hand.

- If it is jammed, gently tap the end of the rotor by a soft hammer and see whether it becomes free.

- If it is still not free, remove the cover at the back of the rear plate by removing the three allen screws, and gently tap the end of the rotor by a center punch and a soft hammer.

- If the rotor becomes free to rotate by hand, put back the cover and give air connection to the motor. It should run properly. Connect the gearbox to the motor by putting the screws on the square flange.

- If the rotor does not become free even after light hammering from both the ends, the motor has to be completely opened. It is advisable to send it to our factory for this purose.