- Call Us On

+91 9890135193

- Mail Us On

Advantage of Using Air Motors

- Variable Speed: The speed of an air motor can be changed very easily by changing the pressure of the compressed air or the flow of the compressed air. Simple valves are used. No complicated machinery is required.

- Instantly Reversible: Air Motors can be made to change the direction of rotation during running without any damage to the air motor. A simple direction control valve is used.

- Can be stalled indefinitely: Air motor can be stalled during rotation without any damage to the air motor. When the stalling mechanism is removed, the air motor starts working like before.

- Does not burnout on excess load: If the load on the motor exceeds the permissible limit, the motor simply stalls. It does not burn. When the excess load is removed, the motor starts working like before.

- Compact Size: Air motors are very compact in size and weight as compared to similar electric motors.

- Can be used in any position: Air motors can be mounted and used in any direction.

- Portability: Because of the low weight, air motors can be easily moved from one place to another.

- Low maintenance cost: Air motors have very less maintenance cost as compared to electric motors.

- No fear of electric shocks: Since air motors are not connected to any electric power source, they can be used even in wet atmospheres without any fear of electric shocks.

- Safe for using in hazardous and explosion proof environments

- Cool Running: Air expands after exhaust and produces cool working conditions

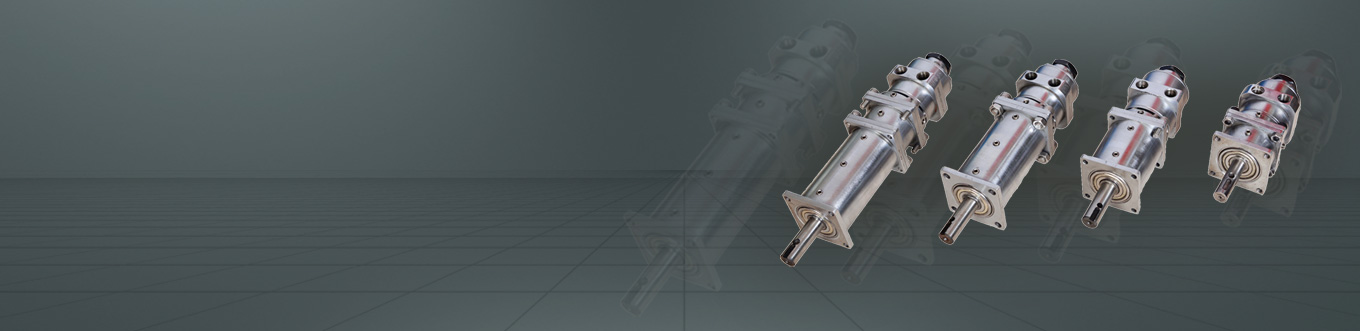

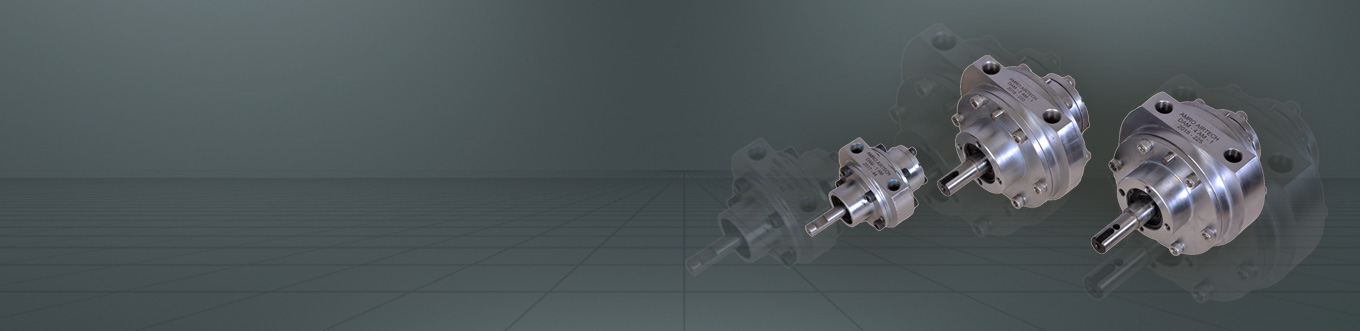

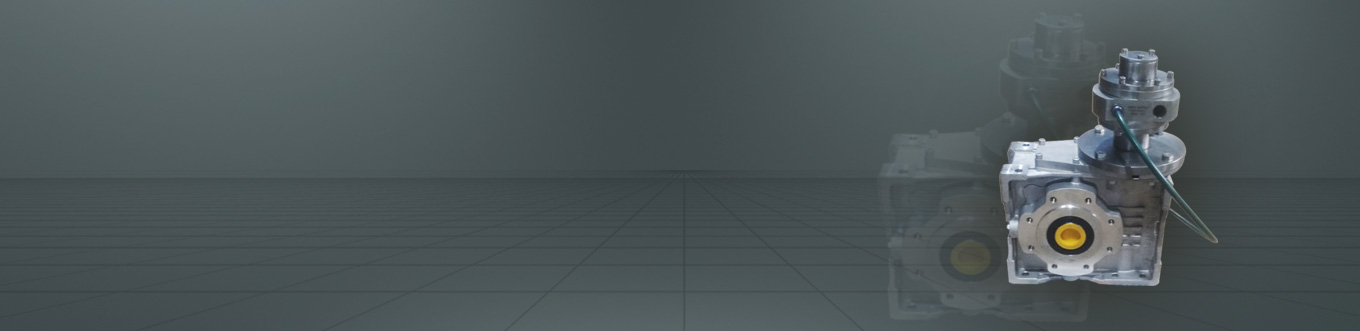

- Air Motors can be coupled with different ranges and varieties of gearboxes such as planetary, bevel, helical or worm gearboxes to give a wide range of speeds and torques.